Igwe na-ejuputa tubes maka plasticlaminate na aluminom tube (ruo 320 ppm)

Nkọwa ngwaahịa

Nkọwa dị nkenke nke igwe na-ekpuchi tube plastik

1. Nkeplastic tube akara igwena-eji ihuenyo mmetụ inch 10 nke Siemens yana ngwanrọ njikwa Japanese Keyence PLC-KV8000.

2. tube nke usoro nchịkwa nchịkwa servo ọrụ na mgbagha njikwa mmegharị

3. Ọrụ nchịkwa: Mgbe e wepụrụ tube ma ọ bụ mmepụta, a ka nwere tube na-anọ na eriri ọkpọkọ - nkwụsị

4. Ọrụ nchekwa (nkwụsị mberede na mgbanaka nchebe) a na-ejikọta ọnụ ụzọ niile mgbe tube nke nkpuchi na-agba ọsọ.

5. igwe na-ejuputa tube akpakaEnwere ike idozi ngwaọrụ mkpuchi niile akọwapụtara site na njikwa njikwa

6. Igwe ọkụ eletrik nke tube nke nchacha nwere ike gbanwee ọsọ ọsọ n'otu n'otu, a pụkwara imezi ngwa ngwa mmepụta nke igwe dum.

7. Ngwaọrụ inching na-arụ ọrụ na obere ọsọ

8. Isi panel iji dozie ntọala mmepụta niile

9. Ogwe ọrụ na-egosiputa ọnụọgụ mmepụta na ọkwa mmepụta ihe

10. Dị ka ndị ahịa chọrọ, setịpụ ọtụtụ usoro nke usoro maka tube nke ndochi

11. Nkeigwe na-ejuputa tube akpakaogwe njikwa nwere ike ịtọ ọrụ oke

12. Igwe na-ejuputa tube akpaka nwere ogwe ọrụ nke 3 dị iche iche na-arụ ọrụ na-echebe.

13. Igwe anaghị agba nchara na-akwụghị ụgwọ eletrik na mkpuchi ikuku, ọkwa nchebe ruru IP65 ma ọ bụ karịa.Igwe eriri USB dị n'etiti igbe eletrik na igwe na-eji eriri USB emechiri emechi, eriri na-abanyekwa n'elu igwe n'ogo dị elu.

N'ọdịnihu, usoro nchịkwa nwere ike iji Siemens profitnet nyefee data na MES ma jikọọ na usoro MES.

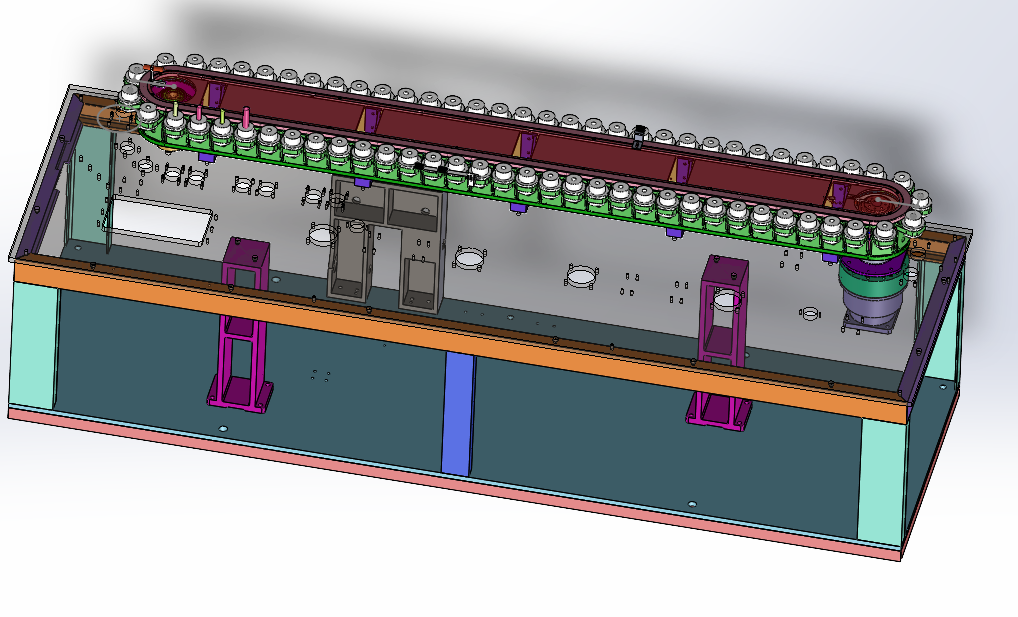

Igwe na-ejuputa tubes maka plasticlaminate na aluminom tube

LFC4002Igwe na-ejuputa tubesbụ igwe na-ejuputa na ọdụ anọ na-ekpuchi igwe zuru ezu servo plastic tube sealing igwe na-emepụta onwe ya, nke ụlọ ọrụ anyị mere ma rụpụta ya.Ọ dị mma maka ijuputa nkọwa dị iche iche nke aluminom-plastic composite tubes na-adịghị mma ma ọ bụ nke na-adịghị mma, tubes plastik na tubes aluminum.Ọsọ imewe bụ tubes 360 / nkeji, yana oke mmepụta ngwa ngwa nke tube nke nchacha bụ 250-340 tubes / nkeji.Izi ezi ndochi bụ ≤± 0.5%.A na-emechi ọkpọkọ aluminum site na mpịachi, aluminom-plastic composite pipe na-ekpuchi ya site na ikuku na-ekpo ọkụ ma ọ bụ ikpo ọkụ dị elu, a na-ekpuchikwa ọkpọkọ plastik site na mkpuchi mkpuchi ikuku ọkụ ọkụ.

Igwe na-ejuputa Tubes Usoro nnyefe isi:

Igwe na-ejuputa tube akpakana-anakwere ụgbọ okporo ígwè alloy steel integral ndu, usoro mgbochi mkpọchi iko iko atọ na-egbochi mkpọtụ, yana usoro 4kW servo na-ebugharị tube iko na-ebufe yinye.Igwe mkpuchi tube plastik na-ekpebi oke ọsọ na nkwụsi ike nke akụrụngwa nkwakọ ngwaahịa.

Tubes Filling Machine tube cup yinye ngwaọrụ na-ebufe ihe nwere ụzọ ntụzịaka elu, ala na akụkụ alloy steel atọ.A na-etinye ihe nrịbama atọ na-agbagharị n'elu oche iko tube, na ebe a na-agbagharị agbagharị na-aga n'ihu n'ime oghere ma kwọọ eriri ahụ.Agbụ iko tube enweghị uwe.A na-enwekwa igwe na-agbagharị agịga abụọ dị elu na nke ala etinyere na ntụtụ maka ntụgharị.

Igwe mkpuchi ọkpọkọ ọkpọkọ eriri igwe na-ebugharị ụdọ na-edozi ma na-edozi oche tube (n'ọnọdụ atọ na-ebu, ụgbọ okporo ígwè ígwè) n'etiti ibe ha site na eriri na-ebu eze.Eriri ebufe eze nwere ezé na-agba ọsọ nke ọma dabere na nfefe nke wiil ịnya ụgbọ ala.A na-etinye iko tube na mgbanaka oche tube ọ bụla.A na-eme iko tube nke ihe POM ma na-ezute nkọwa nke ụdọ na ihe ndị chọrọ imewe.

Tubes Filling Machine ebufe yinye ibu ihe nchebe na-arụ ọrụ site na mbido nloghachi nkenke ihe nrụnye na-arụ ọrụ na wiil nnyefe, nke nwere ogologo ndụ ọrụ.Ọ bụrụ na yinye ọkpọkọ ahụ rapaara, a kwụsịrị njigide ahụ, a na-ebute mgba ọkụ nso, igwe na-akwụsị ozugbo.

Tubes Filling Machine Usoro nhicha n'ịntanetị

1. Igwe mkpuchi tube plastikEnwere ike ihicha sistemu ndochi na hopper ozugbo site na ọdụ CIP na akaghị mechiri emechi n'otu oge.

2. Tupu ịmalite CIP, a na-etinye ihe mkpuchi na-ejuputa na otu CIP dummy cup, na mmiri mmiri na-ehicha ihe ga-esi na igwe na-ejuputa site na pipeline ejikọrọ na CIP dummy cup.

3. Ụlọ ọrụ CIP (nke onye ahịa na-enye) na-enye onye ọrụ nhicha na ọnụ ụzọ nke hopper.A na-etinye bọọlụ ịgba n'ime cylinder ahụ, bọọlụ ịgbasa na-efesa ihe na-ehicha ihe n'elu ime cylinder ahụ.Emebere igwe eji eme ihe na-ejuputa ihe eji eme ihe dị ka ụkpụrụ ịdị ọcha si dị, na mmiri nhicha CIP nwere ike iru n'elu ala, ọkpọkọ na ngwa niile na-abanye na ngwaahịa ahụ n'oge usoro mmepụta.Akụkụ ndị na-abata na kọntaktị na ngwaahịa n'oge mmepụta, dị ka piston nfuli, agitators, wdg, ga-atụgharịkwa otú ahụ n'oge CIP ihicha iji hụ na ihe niile na-ebupụta akụkụ nke na-akpụ akpụ nwere ike ihicha nke ọma.

4. Ọkụ na-ejikọta maka mmiri na-ehicha ihe ka ọ laghachi na usoro CIP nke ndị ahịa (mkpọghachi mgbapụta adịghị etinye n'ime oke nke ọkọnọ).

5. Mepụta usoro nhicha na disinfection dị ka mkpa ndị ahịa si dị, a na-ahazi nhicha na disinfection niile na ọdụ CIP.

6. Parameters dị ka okpomọkụ, nrụgide, ọsọ ọsọ na oge nke usoro CIP nwere ike ịtọ site na ọdụ CIP dị ka ndị ahịa chọrọ.

7. Ngwunye ndochi nke igwe mkpuchi tube plastik nwekwara ike ịwepụ ngwa ngwa site na usoro mgbapụta maka nhicha offline.

8.CIP okporo ụzọ chọrọ 2T / H ma ọ bụ n'elu

Igwe na-ejuputa Tubes na-eji robots na-enye nri tubes (tube 15 × 2 a na-ewere n'ahịrị abụọ oge ọ bụla, oge 9-12 / nkeji):

Dị ka usoro ihe omume ahụ si dị, rọbọt ahụ na-ewepụta ahịrị abụọ nke hoses n'igbe tube a kapịrị ọnụ mgbe ọ bụla, na-ebufe ha n'elu iko tube ahụ, wee tinye ha n'ụzọ kwụ ọtọ n'ime iko tube.Robot na-eji usoro nkwado tube, ma na-eji igwe anaghị agba nchara mee ka mkpịsị aka ya sie ike.Emepụtara, enwere ike ịkwasa maka ihicha na mkpochapụ ma ọ bụ mebie ya na mmiri hydrogen peroxide.

The grating na-achọpụta ma ọ dị tubeleft na mkpịsị aka rọbọt nke etinyeghị n'ime iko tube ahụ, ma mee ka usoro extubation ahụ wepụ eriri ahụ na mkpịsị aka, wee gaa n'ihu iburu tube ahụ.

Igwe na-ejuputa Tubes LFC4002 nwere uru ndị a:

a.Sistemụ njikwa: tube nke ndochi na-anabata ihuenyo mmetụ Siemens na njikwa ngagharị nke Japanese Keyence, ụgbọ ala servo zuru oke;mkpọtụ ahụ erughị decibel 75.

b.Usoro ntinye aha: tube nke filler na-eji usoro servo dị ka onye na-edepụta ihe, ma na-emepụta sọftụwia dị iche iche iji mee ka ike dị ike na static ratio, gbatịa oge static nke ndochi na akara, ma hụ na ngwa ngwa ngwa ngwa dị n'elu 260pcs / min.

c.Ụgbọ okporo ígwè nke iko iko: Igwe na-ejuputa akpaka akpaka na-arụ ọrụ ọdụ anọ, alloy steel integral rail ụzọ ụgbọ okporo ígwè, yana mgbochi mkpọchi mkpuchi tube iko atọ.

d.Nkewa nke ebe: eriri na-ehicha onwe ya, ihe ntanetị nke robot tube, servo flap tube loading, akpaka tube akpaka, ndochi na akara, servo tube na-ekpochapụ na mpaghara ndị ọzọ na-ekewa dị ka GMP chọrọ.

e.Ndokwa igbe ọkpọkọ: igwe na-ejuputa tube akpaka na-eji ụgbọ njem okpukpu abụọ.A na-ebufe igbe hose ahụ n'elu oyi akwa, na-etinye ya n'elu ikpo okwu na-achọsi ike, na igbe na-enweghị ihe ọ bụla na-eweghachite na ala oyi akwa.

f.Usoro ntinye nke tube: Igwe na-ebu ihe igwe ma ọ bụ tube na-abanye na tubes, ma nwee ike ịchekwa tubes 3000-4000.

h.servo benchmarking: mgbama njide agba agba na-arịa ọrịa, nnukwu ntụgharị servo torque, nnukwu ọsọ na nkwụsi ike.

i.Ihe ndochi nke Servo: Igwe na-ejuputa tube akpaka na-anakwere servo mbanye zuru oke na njuputa seramiiki zuru oke, nke na-agaghị agwụ agwụ.

j.Aluminium pipe clamping and flatting: The clamping and flattening method of the tail sealing device was first a scissor-type clamping flattening, nke nwere ike itinye ikuku n'ime tube ngwa ngwa.Ugbu a, a na-agbanwe ya ka ọ bụrụ usoro nkwụsịtụ na nhazi nke kwụ ọtọ, nke na-enweghị uzuzu na-ezere ịkwọba gas n'ime tube.

k.Aluminom tube ọdụ akara: Mgbe ị na-emechi ọdụ ahụ, mpịakọta na njigide na-anakwere mmegharị ahịrị kwụ ọtọ na-eduzi (nke mbụ ụdị arc pick-up) na-ebulighị tube ahụ elu.Nke a dị mma karịsịa maka ọdụdụ atọ.

n.Ngwaọrụ na-ebugharị: servo na-ewepụ eriri ụzọ anọ ma nwee ọrụ jụrụ.

o.Mbufe mmekọrịta: servo intermittent ije, ebufe mmiri dị iche iche, ezigbo mmekọrịta.

p.Nrụgide nrụgide: na-anabata usoro mmeghe ngwa ngwa nke ọkpọkọ nkesa iji jikọọ na mgbapụta ndochi.

q.CIP dị n'ịntanetị: Enwere ike ihicha ya na ntanetị ma ọ bụ na-anọghị n'ịntanetị.

Nka nka

- Tubes Filling Machine Isi akụrụngwa teknụzụ akụrụngwa

| No | oke | okwu | |

| Nkọwa nke tube (mm) | Dayameta 13 ~ 30, ogologo 60 ~ 250 |

| |

| Ndokwa akara agba (mm) | ±1.0 |

| |

| Ike njuputa (ml) | 1.5 ~ 200 (Zute nkọwa 5g-50g, nkọwapụta na nha dị iche iche na teknụzụ) |

| |

| Ndochi ziri ezi (%) | ≤±0.5 |

| |

| Akara ọdụ | Mpịakọta nke okpukpu abụọ, okpukpu atọ, na nke yiri saddle dị. |

| |

| Ike mmepụta PPm | 250-300 |

| |

| tube kwesịrị ekwesị | Aluminom ọkpọkọ Plastic ọkpọkọ Aluminom plastic ọkpọkọ |

| |

| Oriri ike (kW) | tube nke ndochi | 35 |

|

| Robot | 10 |

| |

| Ike | 380V 50Hz |

| |

| ikuku mgbali | 0.6MPa |

| |

| Oriri ikuku (m3/h) | 20-30 |

| |

| Ụdị yinye nnyefe | (Esi Italy ebubata) Ụdị belt synchronous rebar (servo drive) |

| |

| usoro nnyefe | Mbanye servo zuru oke |

| |

| size (mm) | Ogologo 3700 Obosara 2000 elu 2500 |

| |

| Mkpokọta ibu (kg) | 3500 | ||

Smart zhitong nwere ọtụtụ ndị na-emepụta ọkachamara, ndị nwere ike ịmepụtaIgwe na-ejuputa tubesdị ka ezigbo mkpa nke ndị ahịa

Biko kpọtụrụ anyị maka enyemaka efu @whatspp +8615800211936

Ụdị ngwaahịa

-

E-mail

-

Ekwentị

-

N'elu

0086 15800211936

0086 15800211936